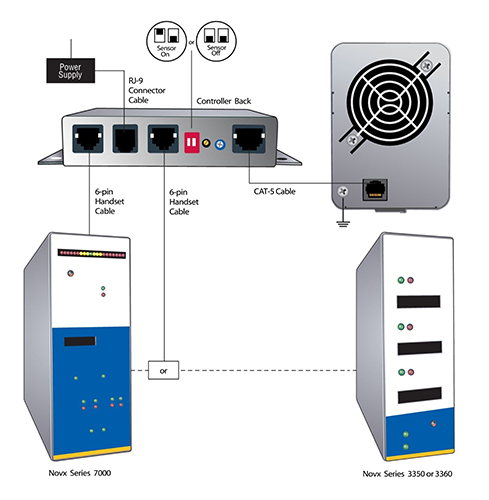

The Model 5822i is designed to control electrostatic discharge and particle contamination for smaller target areas and/or workbench coverage in critical environments like cleanrooms. The modular remote Control Box was developed to accommodate

limited tool footprints. The Control Box connects to the optional

Novx Process Monitor Series 7000 and Novx Passive/Active Field

Voltage Detection System Series 3350/Series 3360 and common

FMS (facility monitoring system) interfaces.