Learn more about ionization here

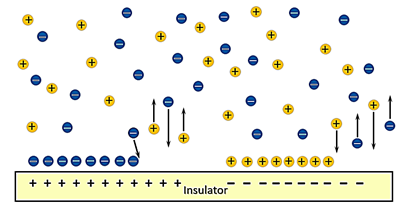

Air ionization is increasingly being used to control or neutralize static charge found in critical environments. Ionizers actually make the air sufficiently conductive to dissipate static charge on both insulators and isolated conductors. All air ionization systems work by flooding the atmosphere with positive and negative ions. When the ionized air comes in contact with a charged surface, the surface attracts ions of the opposite polarity. As a result, the static electricity that has built up on products and equipment is neutralized. Air ions can be produced by a phenomenon called “corona discharge” where a high voltage is applied to a sharp point or to the length of a wire. An electrostatic field is created around the point or wire that can move ions to the work area or conversely some type of airflow can be used to move the ions more efficiently. Corona ionization is commonly found in 3 different forms, alternating current (AC), steady state direct current (DC), and pulsed DC. Each of these methods is used in a variety of ionization products and applications.

Some ionization devices require airflow to operate properly while others do not. If ionizers that require airflow are chosen, they must depend on available airflow or include fans in their design. It must be determined whether fans for distributing air ions are compatible with the work environment. Compressed gas ionizers will require a gas source (usually air or nitrogen) and filtration compatible with their use area.

The moisture content in the air affects the conductivity of certain insulating materials and their ability to hold static charge. The higher the relative humidity (>50%), the higher the conductivity of these materials. Conversely, the lower the humidity (<30%), the more insulative these materials become and the more charge they hold.

Logically, it would follow that high humidity would be an effective means of controlling static. However, even under high relative humidity, unacceptable levels of static charge can be generated and remain for long periods of time. Additionally, high humidity can contribute to other problems including oxidation and soldering difficulties. Using high humidity as a means to control static charge is slow, uncomfortable, expensive, and often ineffective.

No single method exists for controlling all static problems. The proper use of equipment and remedial procedures help cure most static problems.

Grounding: Static on a conductor can be easily controlled if the object is grounded. Grounding provides a path so that charge can migrate to ground, effectively neutralizing the charge. However, grounding an insulator does not work, because charges do not migrate on insulators.

Antistatic or static dissipative materials: Insulative materials, usually plastics, that are made conductive with the addition of carbon or metal fillings. The conductive dispersion can be adjusted depending on the amount of fillings added to provide resistivity ranging from fully conductive to dissipative.

Ionization: Air ionizers work by flooding the atmosphere with positive and negative ions. These ions are attracted to ions of the opposite polarity on a charged surface. As a result, the static electricity that has built up on products, equipment and surfaces is neutralized.

Education: Training personnel and making them aware of electrostatic issues and the need for antistatic gloves, suits, smocks, and wrist/heel straps can make a large difference in the amount of problems that occur in a production facility.

The most common method of charge generation is triboelectric charging. Whenever materials are brought into close contact, a charge exchange may occur between the surfaces of the two materials. The magnitude of this charge exchange will depend on a number of factors, but the result is two oppositely charged objects when the materials are separated.

The second common method of creating static charge is known as inductive charging. This occurs when a charge is "induced" on an isolated conductive object that is brought into the field created by the charge on another object.

There is no "best ionizer technology" for all applications. The application will determine the appropriate type to use. You may want to begin by reviewing the ESD Association advisory document ADV3.2-1995 that covers many of the issues involved in the selection process. Topics cover:

- Charge Neutralization. How effective is the ionizer at reducing static charge?

- Impact on static problem. Does the ionizer help reduce or eliminate the static problem?

- Environmental considerations. Does the environment use laminar, turbulent, or even no airflow?

- What class cleanroom do you have?

- Intallation considerations: Distance, power distribution and control.

- Operation: safety considerations, particle emissions, maintenance, reliability, and warranty, cost.

Electrostatic charge results in electrostatic attraction (ESA), electrostatic discharge (ESD), and electromagnetic interference (EMI). The presence of these problems in the production environment results in destruction to sensitive devices, lock-up or malfunction of microprocessors, product flow or machinery operation problems, and particle contamination.